-

ProductContact UsWith its reliable sealing product material performance and optimized product structure, the company successfully serves in metallurgy, machine tools, rubber machinery, oil and gas, food and pharmaceutical industries.

-

IndustriesContact UsWith its reliable sealing product material performance and optimized product structure, the company successfully serves in metallurgy, machine tools, rubber machinery, oil and gas, food and pharmaceutical industries.

-

Contact UsWith its reliable sealing product material performance and optimized product structure, the company successfully serves in metallurgy, machine tools, rubber machinery, oil and gas, food and pharmaceutical industries.

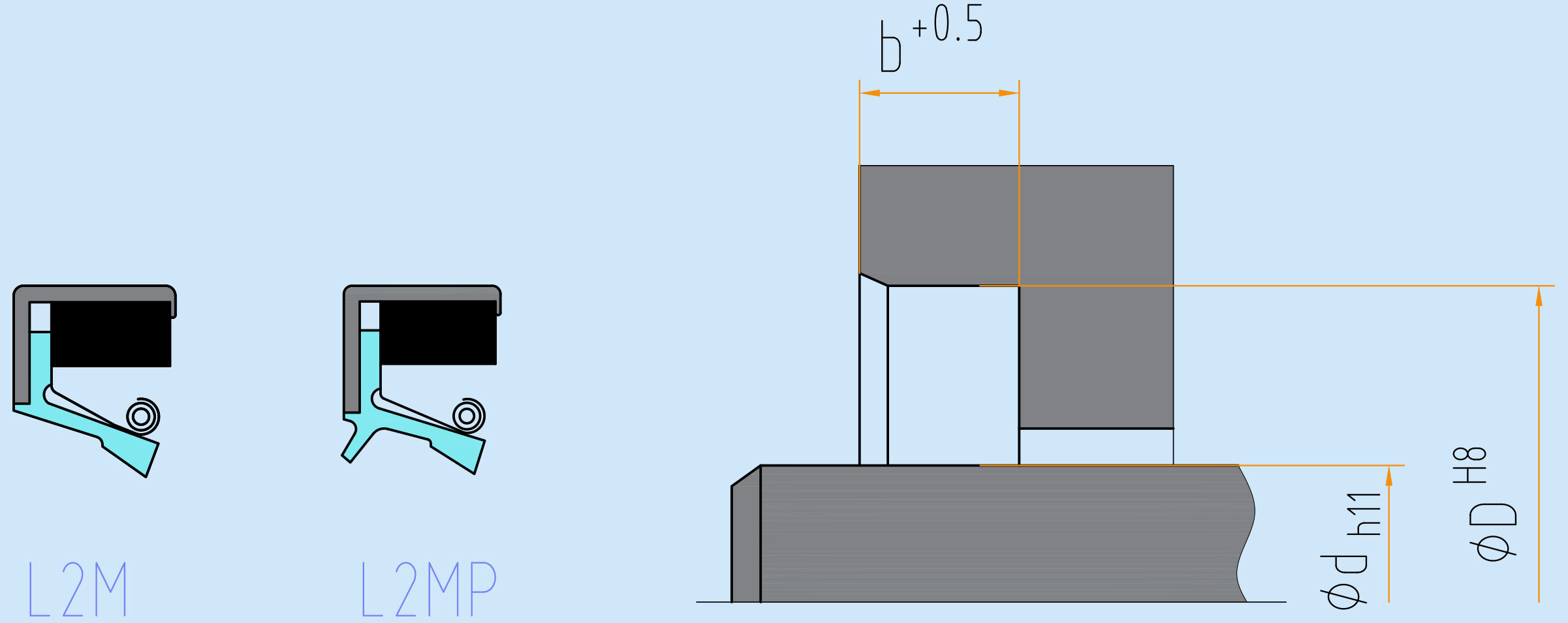

| L2M/L2MP Product Features | |

| L2M/L2MP seals are specifically designed for harsh operating conditions. They are developed for use in applications with high shaft speeds and significant eccentricity. These seals are primarily used in the shaft ends of papermaking machinery, cold rolling mills, hot rolling mills, and other heavy industrial equipment. |

|

| The lifespan and performance of a lip seal largely depend on the preload on the sealing lip in contact with the shaft. In this regard, the L2M/L2MP series, with its combination of high-elasticity leaf springs and coil springs, offers significant advantages over conventional spring-loaded seals, such as improved heat dissipation. | |

| Shaft eccentricity (shaft deformation, bearing clearance, runout, etc.) can cause variations in the preload on the lip against the shaft. For conventional seals, this can lead to lip tilting or reduced service life. The combination of leaf springs and coil springs in the L2M/L2MP series significantly compensates for changes in lip preload due to external forces. Therefore, it ensures the stability of the oil film under the lip, significantly improving the seal's lifespan and sealing performance. Even under very poor concentricity conditions, the maximum permissible speed of the L2M/L2MP series can reach 35 m/s. When installing the L2M series seal on a long shaft or in a deep cavity, the combined structure of the coil spring and leaf spring ensures that the coil spring does not misalign. | |

| The leaf springs and coil springs of the L2M/L2MP series seals are all made of stainless steel. With the leaf springs clamped, the seal lip is firmly bonded to the metal skeleton. This eliminates potential leakage problems in the sealing device. These assembled seals are typically installed using a tapered mounting ring. |

| Application Conditions | |||

| Medium | NBR | MVQ | FKM |

| Mineral Oils | -30℃ ~ +100℃ | Not Applicable | -10℃ ~ +180℃ |

| Water | +5℃ ~ +100℃ | -50℃ ~ +180℃ | +5℃ ~ +100℃ |

| Lubricating Greases | -30℃ ~ +100℃ | Not Applicable | -10℃ ~ +180℃ |

| Pressure Mpa | 0.05 | ||

| Rotational Speed m/s | 20 | 25 | 35 |

| Shaft and Housing Tolerance | |||

| Shaft Diameter φ (mm) Maximum Allowable Eccentricity: 2.5mm | ≦100 ±0.080 | Housing Inner Diameter (mm) | ≦76 ±0.025 |

| 101~150 ±0.100 | 77~150 ±0.040 | ||

| 151~250 ±0.130 | 151~255 ±0.050 | ||

| ≧250 ±0.250 | 256~510 +0.05/-0.10 | ||

| 511~1015 +0.05/-0.15 | |||

| >1015 +0.05/-0.25 | |||

| Surface Finish | ||

| Speed (m/s) | Maximum Roughness | Hardness |

| Ra(μm) Rmax(μm) | HRC | |

| ≦10 | 0.5~0.6 2~3 | 40 |

| 11~16 | 0.3~0.5 1~2 | 50 Overall Grinding |

| >16 | 0.2~0.3 0.8~1 | 55~60 |

L2M/L2MP Specification Table

Product classification

Label List

Previous Page

None

Next Page

Free inquiry