Machine tools

Forming machine as a sheet metal, plastic, wood and ceramic hydraulic power forming equipment more and more appear in the stage of equipment manufacturing industry. With the rapid development of the automobile, aircraft manufacturing, aerospace, and shipbuilding industries, the requirements for customization of molding machines are getting higher and higher, especially the requirements of high pressure, high speed and high efficiency put forward higher requirements for the sealing industry in the field of molding machines. Excellent molding machine custom sealing solution capabilities and high quality sealing materials are the key to ensure the success of every key project. For standardized production of injection molding machines and bending and shearing machines, high stability and longer life requirements are required.

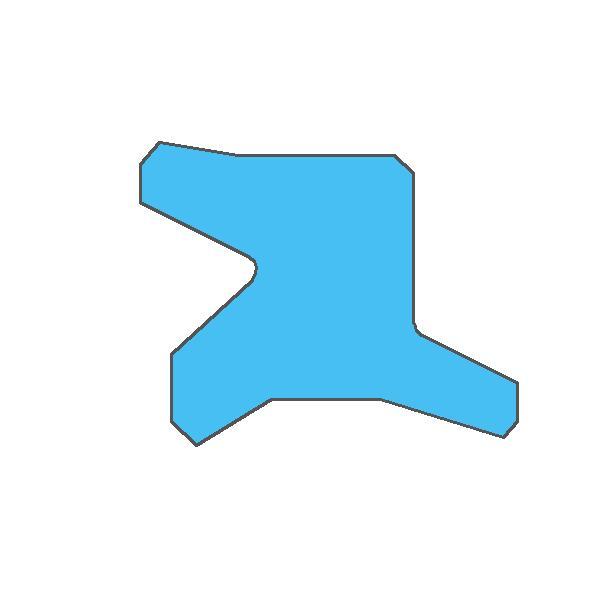

forging press

Senior forging press seal design experts tailor-made for you ultra-high pressure, large gap, large diameter and other special requirements of the hydraulic seal program

Ceramic press

In view of the severe working conditions, dust pollution and the deflection challenges faced by the oil cylinder under higher pressure, a special sealing scheme is designed to solve the leakage troubles of the oil cylinder with high strength and continuous work.

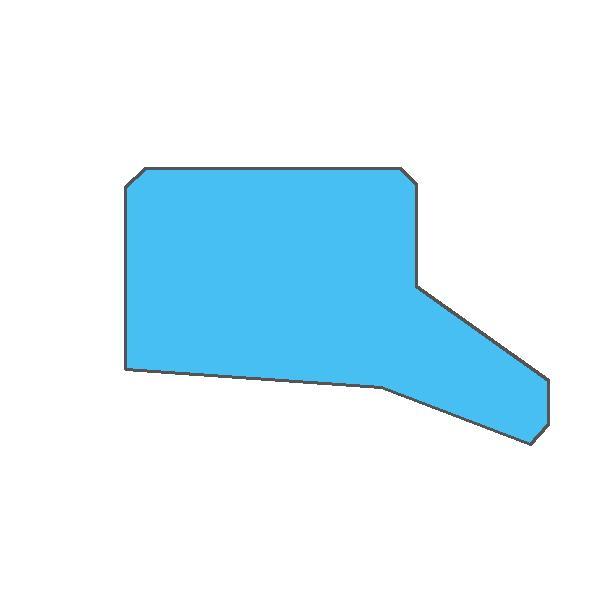

Plate press

How to ensure that the continuous plate press can work normally under high strength and continuous time, especially under long-term high temperature use, facing the challenge of water-based hydraulic fluid medium, it is necessary to ensure that the seal reaches zero leakage under poor lubrication environment. We choose high-performance sealing materials with temperature resistance and abrasion resistance and unique seal section design to meet a series of requirements

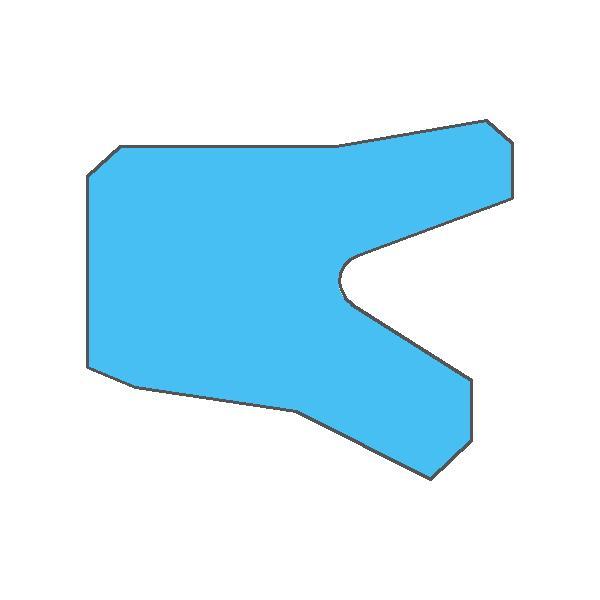

bending and shearing machine

Without exception, a standardized product line requires very high reliability and stability to ensure that every device has the same performance and user experience. High wear resistance, anti deformation, cost-effective sealing form and material is the best choice.

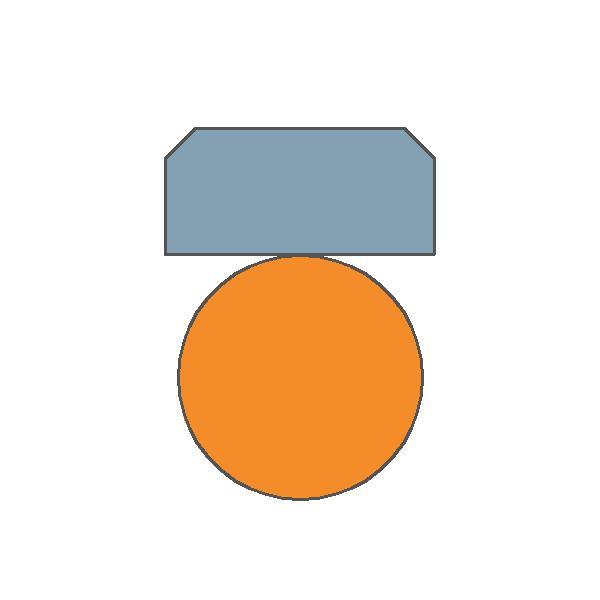

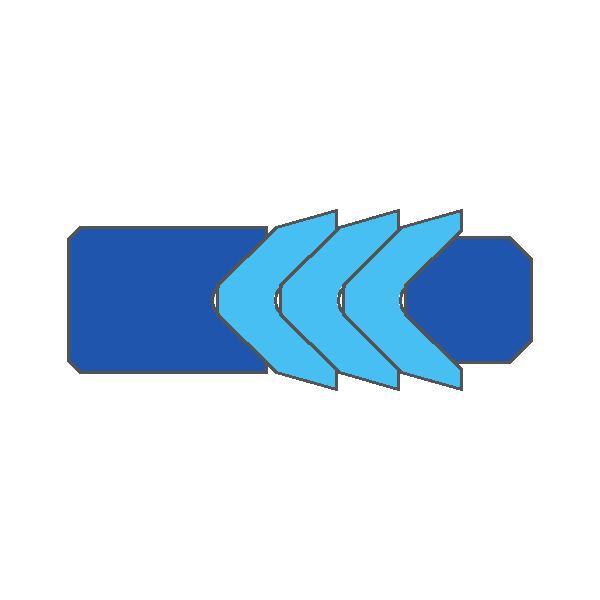

Customized sealing solutions for molding machine applications and sealing materials suitable for molding machine industry-ultra-high hardness polyurethane series seals

The traditional PTFE sliding combination seal is widely used as a standard product. It has superior performance in low friction and non-crawling working environment, but it is difficult to meet the technical requirements of the current molding machine industry in terms of wear resistance, sealing performance and installation. However, the ultra-high hardness polyurethane series seal can well meet these requirements. It has the following advantages:

● Low friction without crawling

● Good sealing performance

● Excellent anti-extrusion performance

● Good abrasion resistance

● Simple installation without tooling

● Low groove finish requirement

● Ultra-high material cost advantage

● No mold, large diameter seal customization

Extensive experiments have proved that XHPU (ultra-high hardness polyurethane) as the sliding ring of TK08/TS09 series seal can replace the combination seal of tetrafluoroethylene under regular hydraulic conditions.

Compared with tetrafluoroethylene, XHPU (ultra-high hardness polyurethane) has superior anti-extrusion performance, allows a larger extrusion gap under high pressure, and has better sealing performance.

In order to meet the low leakage requirements of the seal, the traditional way is to install multiple sealing elements in series to achieve, such as the installation of two seals, or the use of a combination of an elastomer seal plus polyurethane or rubber lip seal. Trygonal XHPU (Ultra High Hardness Polyurethane) seals enable a single sealing solution for a variety of applications.

The good abrasion resistance of the ultra-high hardness polyurethane series seal not only extends the seal life, but also greatly reduces the requirements for the smoothness of the groove and allows a larger extrusion gap, which greatly reduces the production cost. The unique non-abrasive sealing processing technology can provide seals of various sizes at the fastest speed, whether single-piece or batch. This is very consistent with the multi-specification and small batch characteristics of the molding machine. It is a sealing choice you can trust in the molding machine industry!