petroleum and petrochemical

As we all know, the requirements of the oil and gas industry for seals are almost harsh. Not only is the seal required to have excellent sealing performance, but also to have higher reliability and longer service life. Through years of research and development, we can provide high-quality seals and sealing materials that meet the requirements of the oil and gas industry.

Our sealing products and solutions have been used in many petroleum installations, including:

● Top drive system

● Christmas tree and wellhead devices

● BOP

● Downhole tools

● Fracturing pump and mud pump

● LNG cryogenic valve

Fracturing Pump Seal Application

Fracturing pump is an important equipment for oil field fracturing, acidizing operation, improving oil and gas production and shale gas exploitation. As the important spare parts of the hydraulic end of the fracturing pump, the length of the life directly affects the efficiency and quality of fracturing.

Val Rubber

The service life of the rubber depends on the performance of the material to the fracturing fluid and the physical properties of the material. There are many kinds of fracturing fluids, and each fracturing fluid has more than ten kinds of additives with complex components, and requires good sand carrying capacity. During the fracturing process, the working pressure can reach 15000psi, and each operation time exceeds 2 hours. For the fracturing market acidification, high pressure, high sand ratio conditions to provide two high quality materials for the rubber to choose from, its wear resistance, high pressure resistance, impact resistance and acid resistance has a good performance.

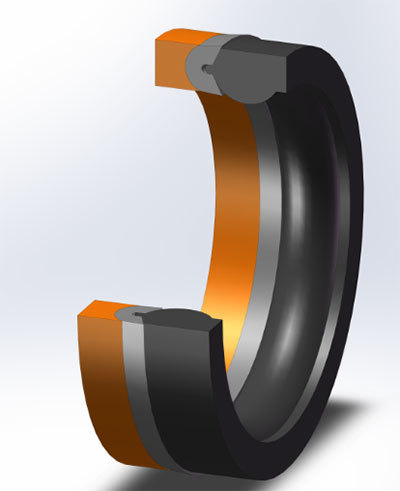

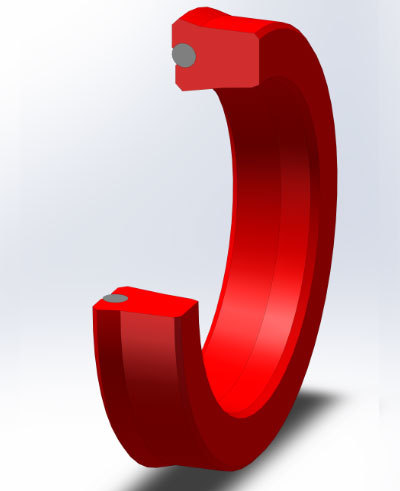

Plunger Packing

The service life of the rubber depends on the performance of the material to the fracturing fluid and the physical properties of the material. There are many kinds of fracturing fluids, and each fracturing fluid has more than ten kinds of additives with complex components, and requires good sand carrying capacity. During the fracturing process, the working pressure can reach 15000psi, and each operation time exceeds 2 hours. For the fracturing market acidification, high pressure, high sand ratio conditions to provide two high quality materials for the rubber to choose from, its wear resistance, high pressure resistance, impact resistance and acid resistance has a good performance.

Common packing size specification table

TR09F

TR10F

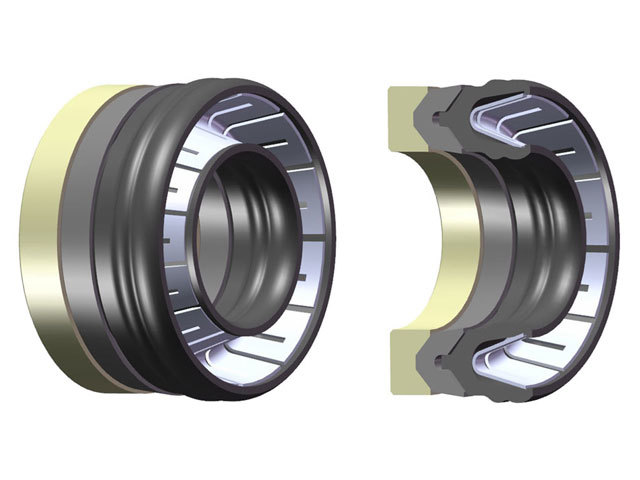

Top Drive

The rotary seal and rotary fluid seal specially developed for the top drive unit can greatly improve the leakage caused by the aging failure of the seal caused by long-term continuous operation, and the short life problem of the seal in the extreme cold climate working environment, providing a reliable sealing solution for the -50 degree extreme cold climate.

TR09-F

TR10-F

TR01-F

Wellhead Sealing Applications

FS/S seal is suitable for casing head seal. HNBR and stainless steel spring are used for vulcanization. It has stronger high pressure resistance, is easy to install and does not need grease injection maintenance. The use and pressure are between 5,000-15,000psi.

FS Seal

S Seal

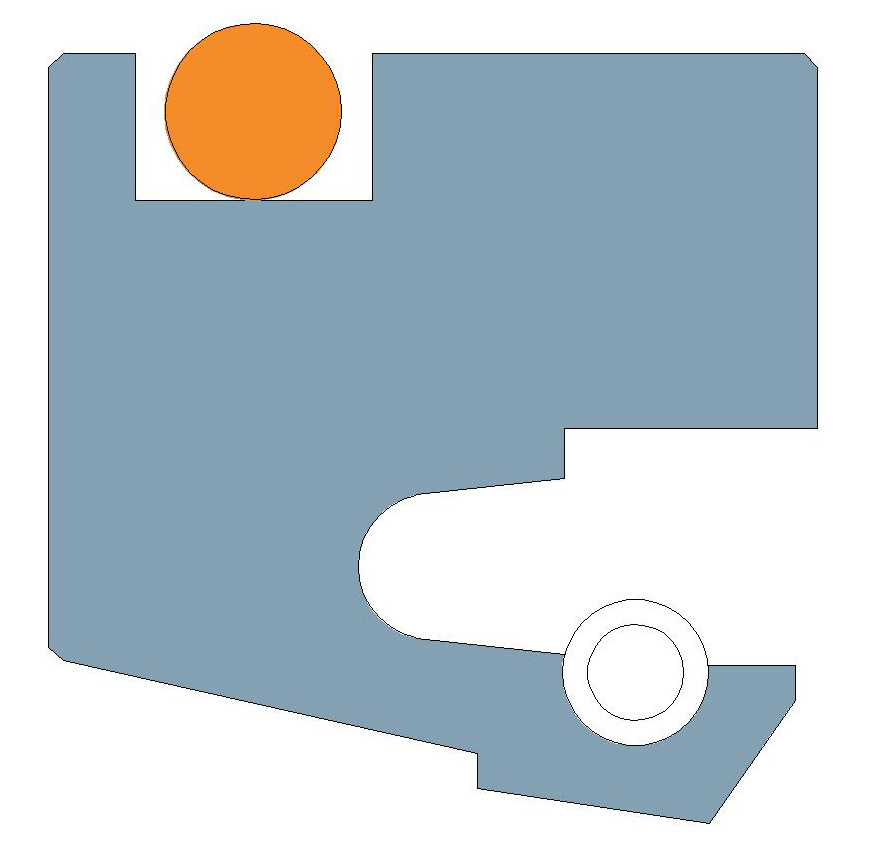

T seal

Compared with the S-type seal, it can withstand higher pressure and temperature, while avoiding damage to metal components, and has better performance. The unique mold-free production process can make the temperature range wider and the pressure level higher; the unique retaining ring design has Self-locking function, easy installation, can avoid cutting the retaining ring during installation.

BOP Seal Application

Ram and annular blowout preventers need more reliable sealing solutions to cope with temperature changes and complex media environments during drilling, and more importantly, to seal zero leakage under low pressure conditions. The large-diameter sealing ring produced by the mold-free process can well meet the needs of large-diameter annular blowout preventer sealing, and win valuable time for the time-consuming and costly equipment disassembly work.

Flat Gate Valve Sealing Applications

Valve stem and valve seat seals are used in various pressure control applications during drilling or oil production. The pressure resistance of such seals can be as high as 20,000psi. The modified PTFE material and PEEK are used as main sealing materials, and the Elgilog spring can be applied to LU temperature grade valves of -46-121 degrees, and need to pass API 6A PR2 test.

U-shaped sealing ring

SH type sealing ring

SI type sealing ring

SB type seal ring

Application Of Downhole Tool Sealing

Seals for downhole tools usually need to be exposed to drilling fluid or withstand extreme temperatures and high pressures, and the requirements for sealing materials are extremely harsh. HNBR, FKM and PEEK are used in large quantities as the main sealing materials in downhole tools. Due to the high cost of downhole drilling equipment, good sealing can ensure normal operation and reduce costs. Such as jar, measurement while drilling, drill bit and a large number of downhole tools.

U-shaped sealing ring

SH type sealing ring

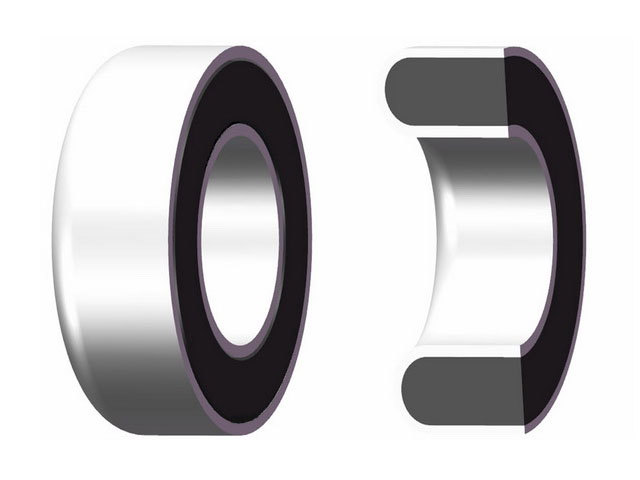

Lng Cryogenic Valve Sealing Application

The normal pressure temperature of liquefied natural gas (LNG) reaches -162 ℃, and the sealing requirements are extremely harsh in transportation and filling, especially the sealing performance test under low temperature and low pressure. The combination of modified high molecular polymer material and Elgilog spring greatly improves the performance of low pressure seal at low temperature.