Food and Medicine

Food is the most important for the people

Trygonal the world leader in the manufacturing of sealing and engineering plastic components, due to its rich experience in sealing technology and sealing materials, Trygonal sealing and engineering plastic components have been successfully applied in the food, beverage, pharmaceutical and packaging industries.

The food and pharmaceutical packaging industry has very strict requirements for sealing and engineering plastic components due to its following particularities:

1. The wide range of media and the characteristics of direct contact with the product require that the materials of the sealing and engineering plastic components have extremely high compatibility and pollution-free characteristics;

2. The highly corrosive chemicals used in the process of cleaning and sterilization and the high temperature environment require that the materials of sealing and engineering plastic components have extremely high corrosion resistance and high temperature resistance

3. In the food, medicine and packaging industries, sealing and engineering plastic components often work without lubrication, so the requirements for wear resistance and sliding performance of materials are extremely high.

4, in order to avoid sealing and engineering plastic components pollution processing products, requirements of sealing and engineering plastic components of the material has a special color, such as white, white or red;

The metering system of the food and pharmaceutical industry requires extremely high accuracy, so it is required that even the sealing and engineering plastic components running under non-lubricated working conditions still have good sliding performance and anti-crawling performance.

The sealing and engineering plastic components used in the food, medicine and packaging industries are required to comply with various national and international food and medicine standards.

trygonal is one of the few manufacturers in the world that provides professional sealing and engineering plastic component solutions for the food and beverage, pharmaceutical and packaging industries.

The unique mold-free processing technology allows us to provide the best sealing products and engineering plastic components in any quantity (from single piece to batch), any size, any section, and any material at the fastest speed. These products meet various international standards in terms of materials and sections, and we guarantee that they are the best sealing and engineering plastic components for your equipment.

High Pressure Homogenizer

The high-pressure homogenizer is also called "high-pressure fluid nano-homogenizer". It can make the material in the suspension state flow through the cavity with special internal structure at high speed under the action of ultra-high pressure (up to 60000psi). Under the action of high-speed shear force and pressure, the particles are more evenly dispersed in the solution, and finally the homogeneous effect is achieved. In the homogenization process, particles or droplets are subdivided into micron-sized particles to form a stable dispersion or emulsion. In order to provide an effective seal, the seal must be able to withstand high pressures and have good sliding properties. In order to handle abrasive food products and aggressive cleaning agents, the seals must be made of materials with high chemical and abrasion resistance. Therefore, the selection and combination of sealing materials is essential to meet performance requirements and food safety regulations.

Sealing Solutions

Our T1R and T2R seals provide a qualitatively improved performance over conventional elastomer seal components commonly used in homogenizers.

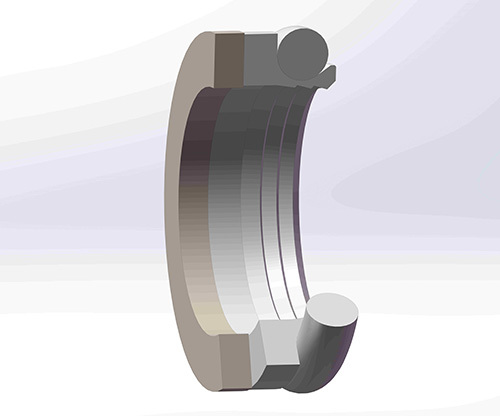

T1R

1. PEEK retaining ring prevents extrusion

2. U-shaped ring resists high load

3. Mineral filled PTFE ring increases redundant sealing and reduces heat

4. UHMWPE sealing ring is wear-resistant

5. PEEK seal ring can wipe fluid and provide flexibility for installation

6. PEEK support ring is suitable for most springs

T1R:

| dh8 | DH9 | L | Rmax | Cmin |

| 15 | 27 | 28 | 0.4 | 1.5 |

| 16 | 28 | 28 | 0.4 | 1.5 |

| 18 | 30 | 28 | 0.4 | 1.5 |

| 20 | 32 | 28 | 0.4 | 1.5 |

| 21 | 33 | 28 | 0.4 | 1.5 |

| 22 | 34 | 28 | 0.4 | 1.5 |

| 24 | 36 | 28 | 0.4 | 1.5 |

| 25 | 37 | 28 | 0.4 | 1.5 |

| 28 | 40 | 28 | 0.4 | 1.5 |

| 30 | 42 | 28 | 0.4 | 1.5 |

| 32 | 44 | 28 | 0.4 | 1.5 |

| 35 | 47 | 28 | 0.4 | 1.5 |

| 36 | 48 | 28 | 0.4 | 1.5 |

| 38 | 50 | 28 | 0.4 | 1.5 |

| 39 | 51 | 28 | 0.4 | 1.5 |

| 40 | 52 | 28 | 0.4 | 1.5 |

| 42 | 54 | 28 | 0.4 | 1.5 |

| 45 | 57 | 28 | 0.4 | 1.5 |

| 48 | 60 | 28 | 0.4 | 1.5 |

| 50 | 62 | 28 | 0.4 | 1.5 |

| 52 | 73 | 42 | 0.4 | 2.5 |

| 53 | 74 | 42 | 0.4 | 2.5 |

T1R:

| 55 | 76 | 42 | 0.4 | 2.5 |

| 57 | 78 | 42 | 0.4 | 2.5 |

| 58 | 79 | 42 | 0.4 | 2.5 |

| 60 | 81 | 42 | 0.4 | 2.5 |

| 62 | 83 | 42 | 0.4 | 2.5 |

| 63 | 84 | 42 | 0.4 | 2.5 |

| 65 | 86 | 42 | 0.4 | 2.5 |

| 68 | 89 | 42 | 0.4 | 2.5 |

| 70 | 91 | 42 | 0.4 | 2.5 |

| 75 | 96 | 42 | 0.4 | 2.5 |

| 79 | 100 | 42 | 0.4 | 2.5 |

| 80 | 101 | 42 | 0.4 | 2.5 |

| 82.5 | 103.5 | 42 | 0.4 | 2.5 |

| 85 | 106 | 42 | 0.4 | 2.5 |

| 90 | 111 | 42 | 0.4 | 2.5 |

| 95 | 116 | 42 | 0.4 | 2.5 |

| 100 | 121 | 42 | 0.4 | 2.5 |

| 105 | 126 | 42 | 0.4 | 2.5 |

| 108 | 129 | 42 | 0.4 | 2.5 |

| 110 | 131 | 42 | 0.4 | 2.5 |

| 115 | 136 | 42 | 0.4 | 2.5 |

| 120 | 141 | 42 | 0.4 | 2.5 |

| 125 | 146 | 42 | 0.4 | 2.5 |

| 127 | 152 | 47 | 0.4 | 3 |

| 130 | 155 | 47 | 0.4 | 3 |

| 132 | 157 | 47 | 0.4 | 3 |

| 135 | 160 | 47 | 0.4 | 3 |

| 140 | 165 | 47 | 0.4 | 3 |

| 145 | 170 | 47 | 0.4 | 3 |

| 150 | 175 | 47 | 0.4 | 3 |

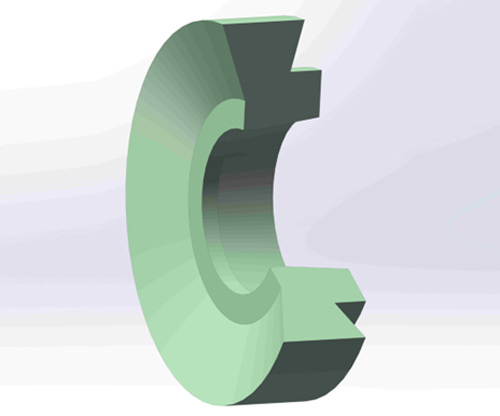

T2R

1. Food grade O-ring elastomer

2. High voltage design

3. The serrated structure can take into account high and low pressure

4. High hardness PEEK anti-extrusion ring

T2R:

| dh8 | DH9 | L | Rmax | Cmin |

| 10 | 20 | 15 | 0.4 | 4 |

| 12 | 22 | 15 | 0.4 | 4 |

| 15 | 25 | 15 | 0.4 | 4 |

| 16 | 26 | 15 | 0.4 | 4 |

| 18 | 28 | 15 | 0.4 | 4 |

| 20 | 30 | 15 | 0.4 | 4 |

| 21 | 31 | 15 | 0.4 | 4 |

| 22 | 32 | 15 | 0.4 | 4 |

| 24 | 34 | 15 | 0.4 | 4 |

| 25 | 35 | 15 | 0.4 | 4 |

| 28 | 38 | 15 | 0.4 | 4 |

| 30 | 40 | 15 | 0.4 | 4 |

| 32 | 42 | 15 | 0.4 | 4 |

| 35 | 45 | 15 | 0.4 | 4 |

| 36 | 46 | 15 | 0.4 | 4 |

| 38 | 48 | 15 | 0.4 | 4 |

| 39 | 49 | 15 | 0.4 | 4 |

| 40 | 50 | 15 | 0.4 | 4 |

| 42 | 57 | 20 | 0.4 | 5 |

| 45 | 60 | 20 | 0.4 | 5 |

| 48 | 63 | 20 | 0.4 | 5 |

| 50 | 65 | 20 | 0.4 | 5 |

| 52 | 67 | 20 | 0.4 | 5 |

| 53 | 68 | 20 | 0.4 | 5 |

T2R:

| 55 | 70 | 20 | 0.4 | 5 |

| 57 | 72 | 20 | 0.4 | 5 |

| 58 | 73 | 20 | 0.4 | 5 |

| 60 | 75 | 20 | 0.4 | 5 |

| 62 | 77 | 20 | 0.4 | 5 |

| 63 | 78 | 20 | 0.4 | 5 |

| 65 | 80 | 20 | 0.4 | 5 |

| 68 | 83 | 20 | 0.4 | 5 |

| 70 | 85 | 20 | 0.4 | 5 |

| 75 | 90 | 20 | 0.4 | 5 |

| 79 | 94 | 20 | 0.4 | 5 |

| 80 | 95 | 20 | 0.4 | 5 |

| 82.5 | 102.5 | 25 | 0.4 | 6 |

| 85 | 105 | 25 | 0.4 | 6 |

| 90 | 110 | 25 | 0.4 | 6 |

| 95 | 115 | 25 | 0.4 | 6 |

| 100 | 120 | 25 | 0.4 | 6 |

| 105 | 125 | 25 | 0.4 | 6 |

| 108 | 128 | 25 | 0.4 | 6 |

| 110 | 130 | 25 | 0.4 | 6 |

| 115 | 135 | 25 | 0.4 | 6 |

| 120 | 140 | 25 | 0.4 | 6 |

| 125 | 145 | 25 | 0.4 | 6 |

| 127 | 147 | 25 | 0.4 | 6 |

| 130 | 150 | 25 | 0.4 | 6 |

| 132 | 152 | 25 | 0.4 | 6 |

| 135 | 155 | 25 | 0.4 | 6 |

| 140 | 160 | 25 | 0.4 | 6 |

| 145 | 165 | 25 | 0.4 | 6 |

| 150 | 170 | 25 | 0.4 | 6 |

Bottle filling machine

Filling bottle head seal

High temperature hydrolysis, Shore 85A hardness polyurethane has high wear resistance, excellent hydrolysis resistance and fully comply with food hygiene standards, because of its low hardness, has good elasticity. Especially suitable for carbonated drinks and pure water filling.

Profile

Physical photo