-

ProductContact UsWith its reliable sealing product material performance and optimized product structure, the company successfully serves in metallurgy, machine tools, rubber machinery, oil and gas, food and pharmaceutical industries.

-

IndustriesContact UsWith its reliable sealing product material performance and optimized product structure, the company successfully serves in metallurgy, machine tools, rubber machinery, oil and gas, food and pharmaceutical industries.

-

Contact UsWith its reliable sealing product material performance and optimized product structure, the company successfully serves in metallurgy, machine tools, rubber machinery, oil and gas, food and pharmaceutical industries.

| PTFE Product Features | |

|

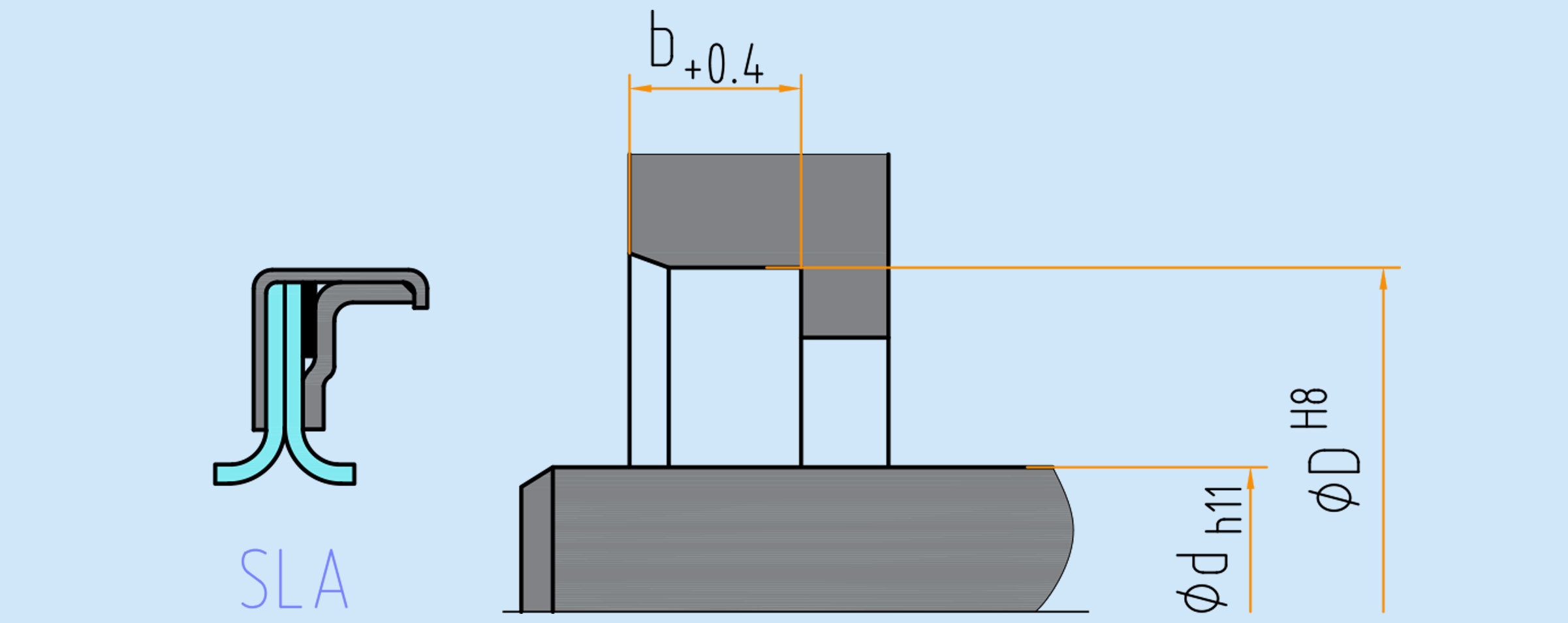

Seal outer edge: Stainless steel metal skeleton; The sealing lip can be made of different PTFE materials according to the operating conditions; Can be installed in open grooves

|

|

| Product Advantages | |

| They are characterized by low friction and stick-slip-free operation, thus reducing heat generation and allowing higher rotational speeds. Low and high temperature range (-60 to +250°C) Can be used at pressures up to 2 MPa; Can be used at rotational speeds up to 40 m/s Wide range of media compatibility, often used in chemical, pharmaceutical and other industries, unaffected by chemicals; Widely used in pumps, separators, blowers, centrifuges, mixers, etc.; |

| Surface Machining Precision | ||

| Surface Roughness | Contact shaft surface | Cavity |

| Ra | 0.1~0.4 μm | <1.6 μm |

| Rmax | 1~4.0 μm | <10.0 μm |

| Rz | 0.63~2.5 μm | < 6.3 μm |

| The material contact area Rmr should be determined to be about 50-70% relative to the baseline Cref at a cutting depth c=0.25xRz. 5%. The sealing pair contact surface should be polished to remove the guiding helix on the shaft surface. It is best to use grinding or only local grinding and polishing on the sealing pair contact surface to avoid leakage caused by the helix generated by mechanical processing. Surface hardness 55-60HRC. |

||

| Product Size Series (Not all sizes are listed in the table, please contact our company for details) |

||||||||||||||||||||||||||||||||||||

| d | 20 | 25 | 28 | 30 | 32 | 35 | 40 | 42 | 45 | 50 | 55 | 60 | 62 | 65 | 70 | 75 | 80 | 85 | 90 | 95 | 100 | 105 | 110 | 115 | 120 | 125 | 130 | 135 | 140 | 145 | 150 | 160 | 170 | 180 | 190 | 200 |

| D | 40 | 45 | 48 | 50 | 52 | 55 | 62 | 65 | 68 | 72 | 78 | 82 | 85 | 90 | 95 | 100 | 105 | 110 | 115 | 120 | 125 | 135 | 140 | 145 | 150 | 155 | 160 | 165 | 170 | 175 | 180 | 190 | 200 | 210 | 225 | 240 |

| b | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 12 | 12 | 12 | 12 | 12 | 12 | 13 | 13 | 13 | 13 | 13 | 13 | 13 | 13 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 16 | 16 | 16 | 16 | 20 |

Product classification

Label List

Previous Page

DLA

Next Page

Free inquiry