-

ProductContact UsWith its reliable sealing product material performance and optimized product structure, the company successfully serves in metallurgy, machine tools, rubber machinery, oil and gas, food and pharmaceutical industries.

-

IndustriesContact UsWith its reliable sealing product material performance and optimized product structure, the company successfully serves in metallurgy, machine tools, rubber machinery, oil and gas, food and pharmaceutical industries.

-

Contact UsWith its reliable sealing product material performance and optimized product structure, the company successfully serves in metallurgy, machine tools, rubber machinery, oil and gas, food and pharmaceutical industries.

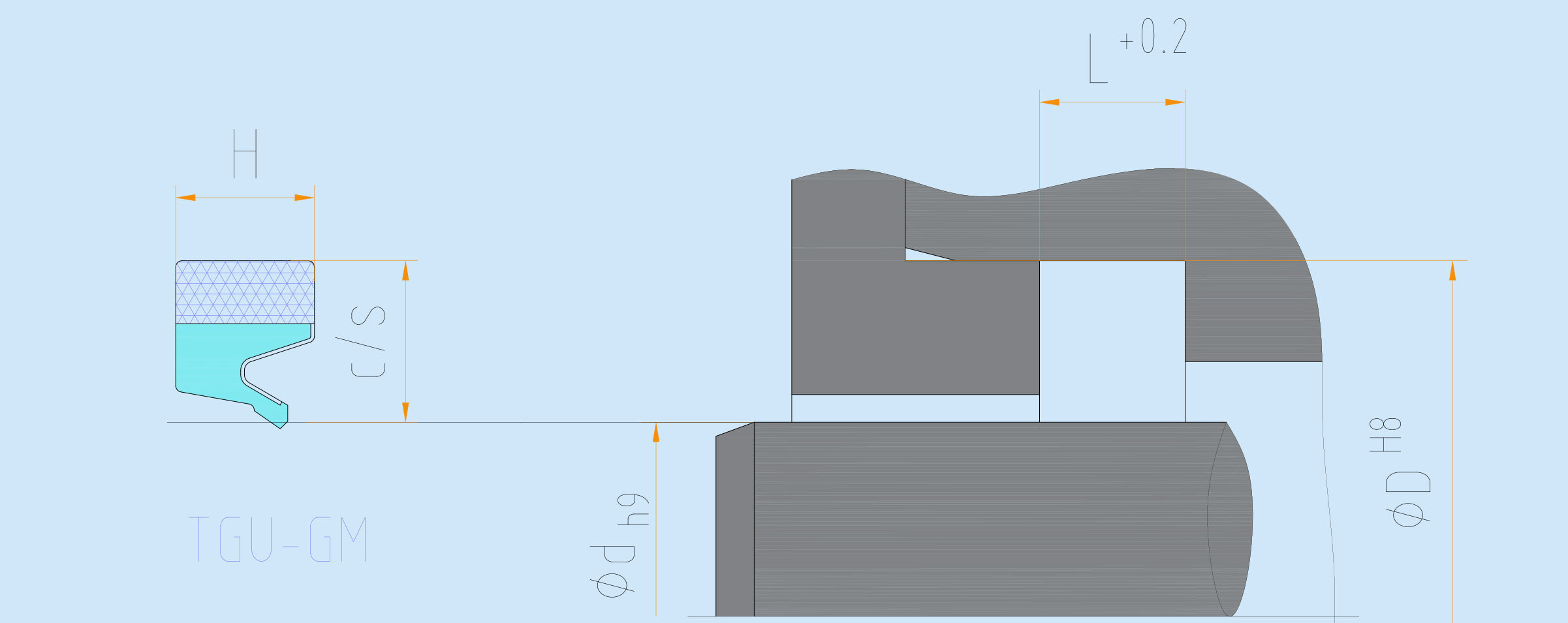

| GM Product Features | |

| GM is a rubber seal product used for rotating shaft sealing devices. It features a boneless, sheet-like stainless steel finger spring vulcanized integrally with the sealing lip. The GM oil seal is a split oil seal with an integrally vulcanized sheet stainless steel spring. It is ideal for applications with difficult on-site installation conditions or where the oil seal needs to be replaced on-site. GM oil seals are best suited for grease lubrication and heavily polluted environments. The integral GM is suitable as a dust seal for hydraulic systems. |

|

| Size | For applications with shaft diameters of φ150~φ1300mm. |

| The following standard sections are available: | |

| 12.5x12.5mm | |

| 15x15mm | |

| 20x20mm | |

| 25x20mm | |

| We can also provide products in imperial units. | |

| Technical Parameters | Maximum linear velocity: 10m/s |

| Maximum eccentricity: 0.2mm | |

| Shaft surface hardness: HRC40 | |

| Shaft surface roughness: Ra=0.3~0.5μm | |

| Rmax: 1~2μm | |

| Installation | Split GM oil seals are manufactured to the required dimensions. During installation, first install the oil seal joint, then carefully install the GM oil seal onto the shaft using a wooden tool. The joint of the split oil seal must always be facing upwards (12 o'clock on a clock face). Generally, we do not recommend cutting the oil seal length on-site. When using GM oil seals, axial positioning should be achieved using a suitable pressure plate. |

| Elastomer | Nitrile rubber and fluororubber are available. |

| TGU-GM Product Size Series |

||

| d | D | H |

| 209.55 | 260.35 | 20.62 |

| 222.25 | 260.35 | 17.45 |

| 266.7 | 298.45 | 15.87 |

| 298.45 | 330.2 | 19.05 |

| 395 | 430 | 18 |

| 560 | 610 | 22.3 |

| 565.15 | 615.95 | 22.22 |

| 635 | 685.8 | 22.22 |

TGU-GM Specification Table

Product classification

Label List

Previous Page

GM

Next Page

Free inquiry