-

ProductContact UsWith its reliable sealing product material performance and optimized product structure, the company successfully serves in metallurgy, machine tools, rubber machinery, oil and gas, food and pharmaceutical industries.

-

IndustriesContact UsWith its reliable sealing product material performance and optimized product structure, the company successfully serves in metallurgy, machine tools, rubber machinery, oil and gas, food and pharmaceutical industries.

-

Contact UsWith its reliable sealing product material performance and optimized product structure, the company successfully serves in metallurgy, machine tools, rubber machinery, oil and gas, food and pharmaceutical industries.

| Product Features |

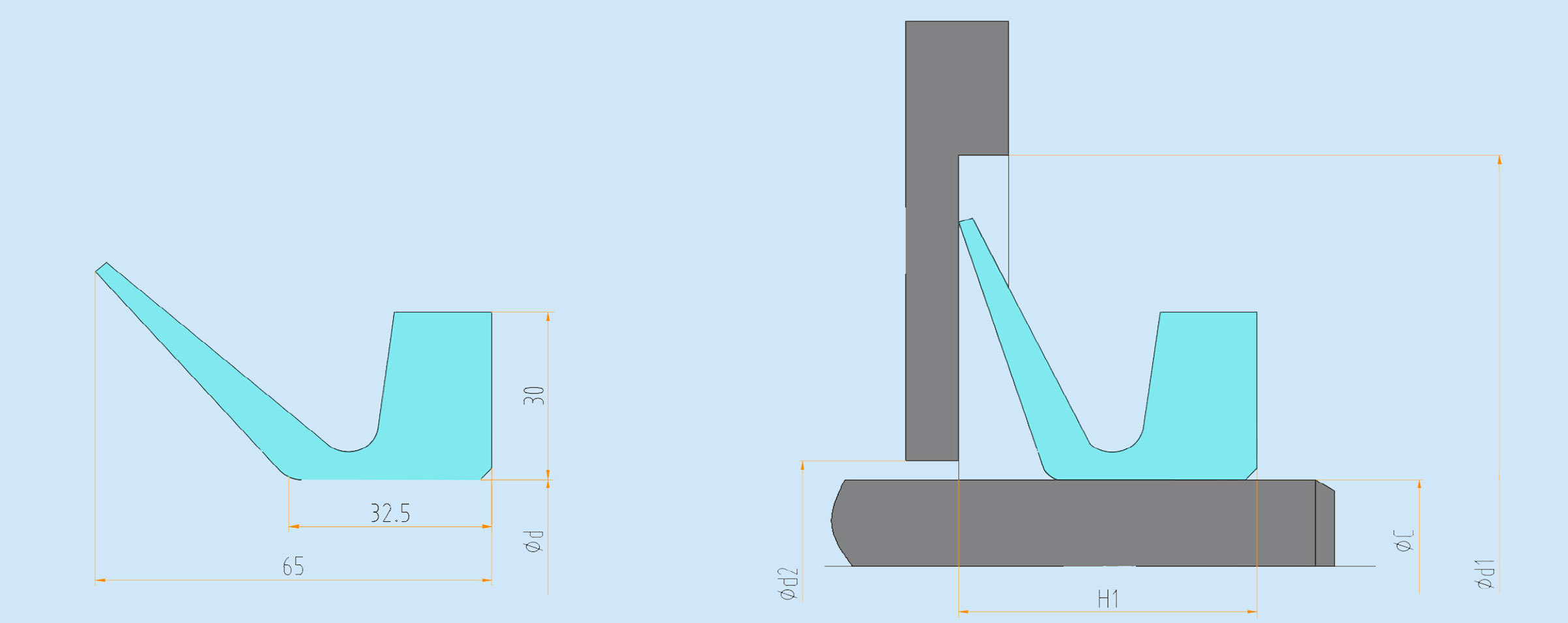

| A water seal is an axial lip seal made of pure rubber material. It is often used for axial end face sealing of the roller shaft head in metallurgical machinery. The water seal relies on its inherent clamping force on the shaft neck to fix it on the shaft neck of the rotating shaft. Simultaneously, it utilizes the bending performance of its lip and the pressing force on the sealing end face to form a sealing pair, thus preventing water and impurities from entering the roller bearing chamber during roller operation, protecting the roller bearings. It meets the requirements of blocking impurities and dust in the cooling water for normal operation. The water seal utilizes the centrifugal force of the cooling water existing outside during the rotation process to block impurities and dust in the cooling water outside the bearing chamber, while preventing the leakage of grease inside the sealing chamber. Commonly used water seals are divided into six types: VA, VS, VL, VE, VAX, and RME. Commonly used materials are neoprene rubber and fluororubber. |

VE Water Seal Specification Table

Product classification

Label List

Previous Page

TGA

Next Page

Free inquiry