-

ProductContact UsWith its reliable sealing product material performance and optimized product structure, the company successfully serves in metallurgy, machine tools, rubber machinery, oil and gas, food and pharmaceutical industries.

-

IndustriesContact UsWith its reliable sealing product material performance and optimized product structure, the company successfully serves in metallurgy, machine tools, rubber machinery, oil and gas, food and pharmaceutical industries.

-

Contact UsWith its reliable sealing product material performance and optimized product structure, the company successfully serves in metallurgy, machine tools, rubber machinery, oil and gas, food and pharmaceutical industries.

| Sealing material | TPU | PTFE | ||

| Surface roughness | Rtmax | Ra | Rtmax | Ra |

| Sliding surface | ≤ 2.5 µm | 0.1–0.5 µm | ≤2 µm | 0.05–0.3 µm |

| Groove bottom | ≤ 6.3 µm | ≤ 1.6 µm | ≤6.3 µm | ≤ 1.6 µm |

| Groove side | ≤ 15 µm | ≤ 3 µm | ≤15 µm | ≤ 3 µm |

| Bearing area: 50-95% and 0.5 Rz cutting depth (based on Cref = 0%) | ||||

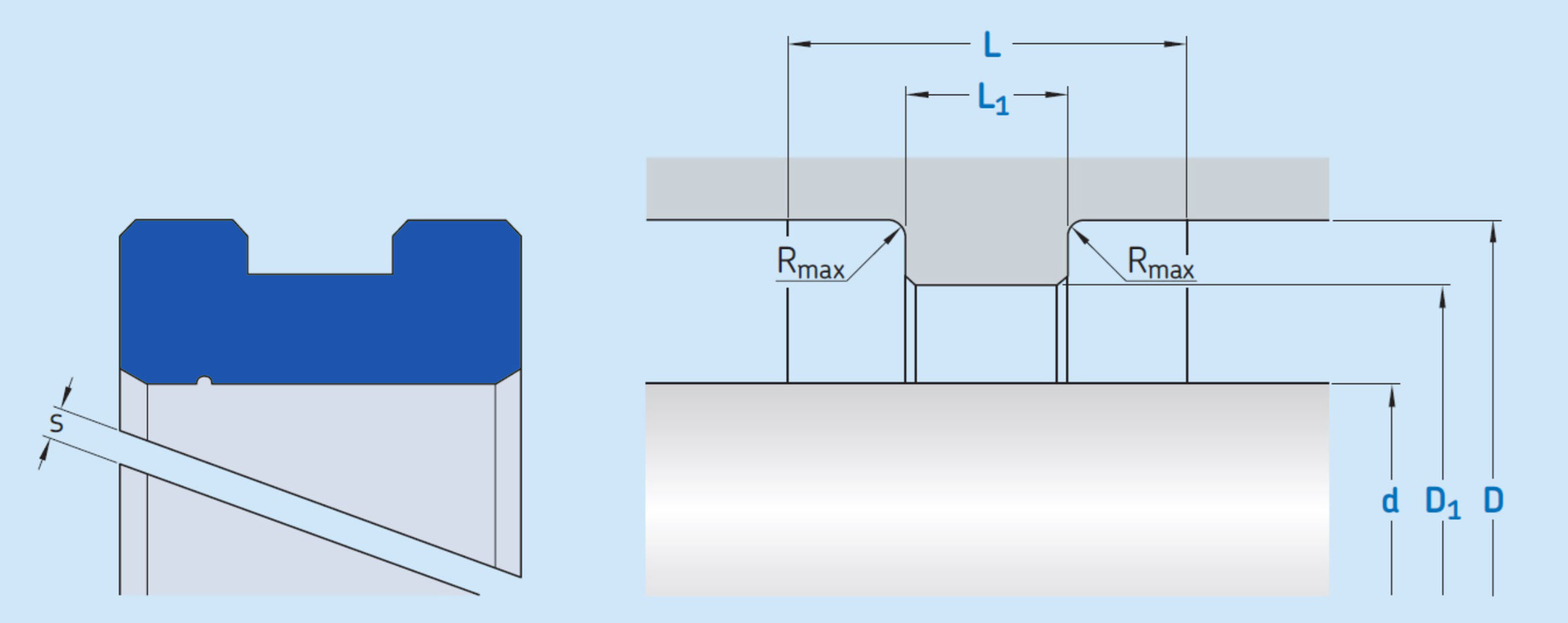

| Recommended size mm | ||||||

| Minimum nominal inner diameter d≥22 mm. Depending on the application, the geometry of the guide element should be adapted to the application type (please refer to the shape description - sealing housing). Because uncut versions are meaningless due to assembly reasons, rotating applications should be avoided. The standard version with a cutting gap of >0 does not allow a support function. In order to achieve the support function, a cutting gap of s = 0 and a spiral groove are provided. The value of the cutting gap depends on the material and temperature. For details, please refer to the profile description. |

| Operating parameters | |||||

| Material | Temperature | Speed | Specific load | ||

| Guide element | Minimum °C | Maximum °C | Maximum m/s | Maximum N/mm2 | |

PTFE g PTFE g |

-200 | +200 | 4 | 3.0 | |

PTFE b PTFE b |

5 | 4.5 | |||

POM POM |

-50 | +100 | 4 | 25 | |

PA PA |

-40 |

||||

Presin Presin |

+130 | 90 | |||

| Ordering example | |

| Introduction | Guide ring TF08 |

| d x D/D1x L/L1[mm] | 100 x 109/103.5 x 15/5 |

| Material | POM |

Previous Page

None

Next Page

Free inquiry