-

ProductContact UsWith its reliable sealing product material performance and optimized product structure, the company successfully serves in metallurgy, machine tools, rubber machinery, oil and gas, food and pharmaceutical industries.

-

IndustriesContact UsWith its reliable sealing product material performance and optimized product structure, the company successfully serves in metallurgy, machine tools, rubber machinery, oil and gas, food and pharmaceutical industries.

-

Contact UsWith its reliable sealing product material performance and optimized product structure, the company successfully serves in metallurgy, machine tools, rubber machinery, oil and gas, food and pharmaceutical industries.

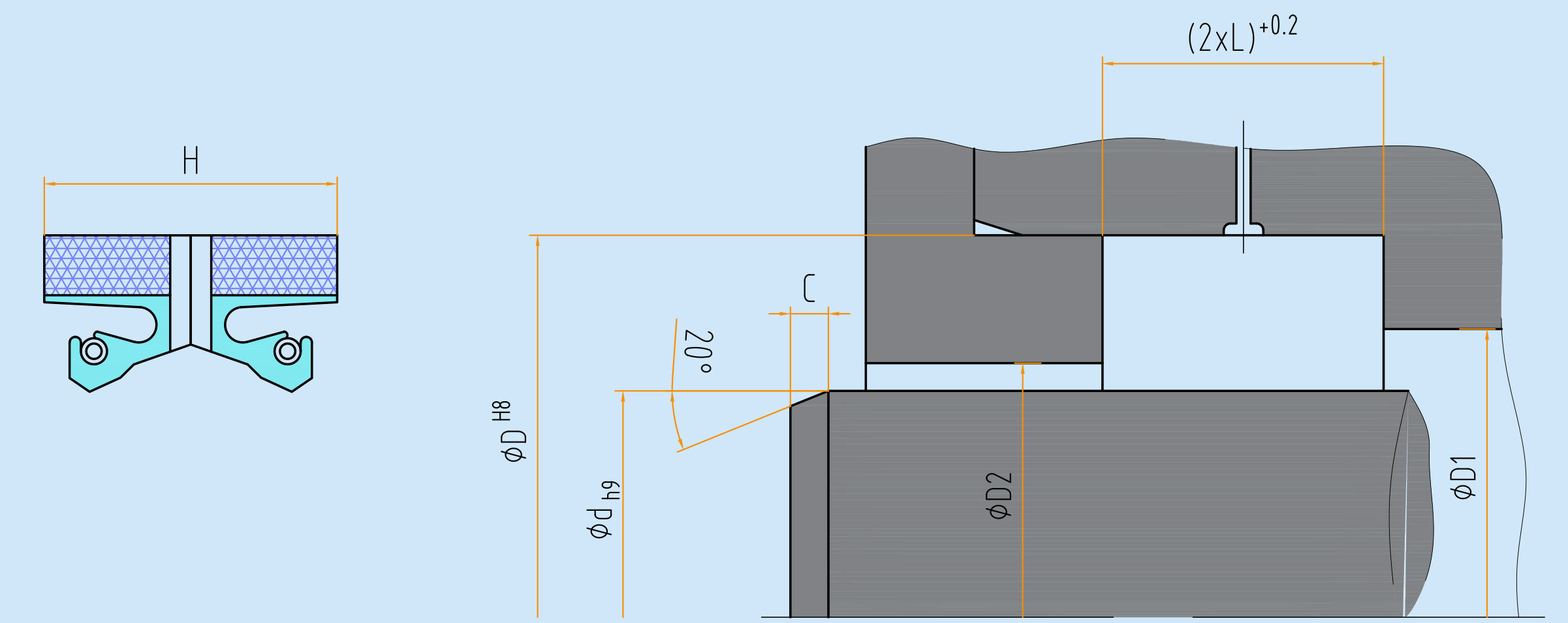

| TGR Product Features | |

| Interwoven fabric reinforced oil seal outer edge shoulder and pure rubber sealing lip integrated design spring pre-loaded oil seal lip design. |

|

| TGR Product Advantages | |

| In the heavy machinery manufacturing industry, they are usually used for the shaft ends of grinders, metallurgical rolling mills, or large gearbox drive shafts with lubrication conditions. The oil seal interwoven fabric outer edge shoulder is particularly strong The radial contact pressure of the oil seal lip is lasting The sealing lip is highly wear-resistant When the sealing lip is designed with a metal support ring, it can withstand higher pressure When under overpressure conditions, it is required to use an integral oil seal without an interface Split seals can be provided for easy installation. Usually installed back-to-back, or two oil seals installed in series |

| Application Conditions |

|||||

| Medium | Mineral oils | Water | Lubricating greases | Pressure Mpa | Rotational speed m/s |

| NBR | -30℃ ~ +100℃ | +5℃ ~ +100℃ | -30℃ ~ +100℃ | 0.05 | 20 |

| FKM | -10℃ ~ +180℃ | +5℃ ~ +100℃ | -10℃ ~ +180℃ | 25 | |

| HNBR | -20℃ ~ +140℃ | +5℃ ~ +100℃ | -20℃ ~ +140℃ | 25 | |

| Please consult for other media. Various parameters should not be used at maximum values simultaneously. | |||||

| Surface machining accuracy | ||

| Surface roughness | Contact shaft surface | Cavity |

| Ra | ≤0.6 μm | ≤4.0μm |

| Rmax | ≤2.5 μm | ≤15.0 μm |

| The sealing pair contact surface should be vertically fed "non-directional" grinding to avoid leakage caused by spiral lines generated by machining. The surface hardness must be close to 60HRC (minimum case hardening thickness 0.5mm). As the circumferential speed increases, the peak-valley height Ra of the contact surface should be appropriately increased. The surface should not be too smooth to form an appropriate oil film. The recommended value is: Ra min=0.1μm. When the cutting depth c=Rz/2 and the reference line Cref=0%, the surface support length ratio Mr >50% to a maximum of 90%. Shaft surface corrosion, scratches and pores must be avoided. |

||

| Installation and Assembly |

| For TGR interwoven fabric oil seals, the cavity must be axial to facilitate axial installation of the oil seal and ensure minimal oil seal tilt.

For reliable sealing function, the actual axial width of TGR is always greater than the nominal Size. TGR oil seals must be axially compressed to Size "L". Open cavities must have a cover plate and be tightened with screws. Appropriate compression deformation force is necessary for the use of TGR. Cover plates and tightening screws must be appropriately designed. |

TGR Specification Table

Product classification

Label List

Previous Page

SC/TC

Next Page

Free inquiry