-

ProductContact UsWith its reliable sealing product material performance and optimized product structure, the company successfully serves in metallurgy, machine tools, rubber machinery, oil and gas, food and pharmaceutical industries.

-

IndustriesContact UsWith its reliable sealing product material performance and optimized product structure, the company successfully serves in metallurgy, machine tools, rubber machinery, oil and gas, food and pharmaceutical industries.

-

Contact UsWith its reliable sealing product material performance and optimized product structure, the company successfully serves in metallurgy, machine tools, rubber machinery, oil and gas, food and pharmaceutical industries.

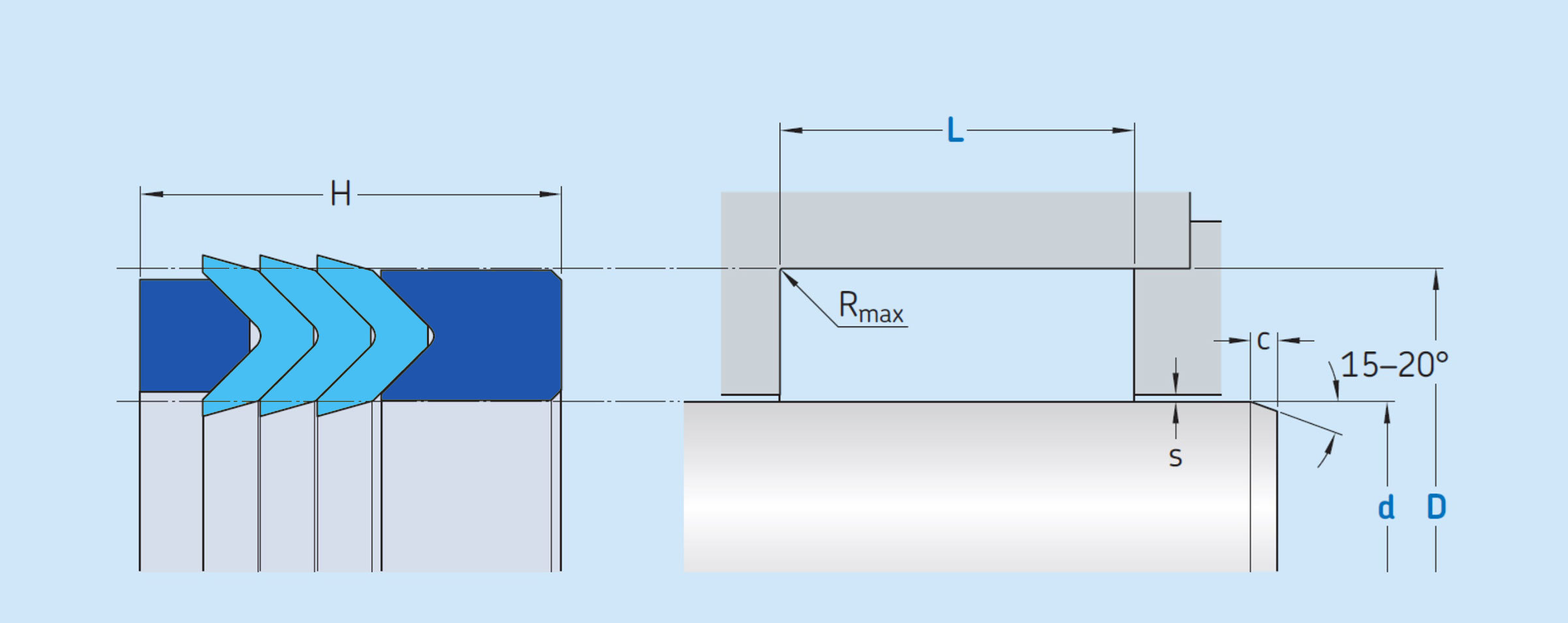

| Surface roughness | Rtmax | Ra |

| Sliding surface | ≤ 2.5 µm | 0.1-0.5 µm |

| Trough bottom | ≤ 6.3 µm | ≤ 1.6 µm |

| Trough side | ≤ 15 µm | ≤ 3 µm |

| Bearing area: 50-95% and 0.5 Rz cutting depth (based on Cref = 0%) | ||

| Recommended Size mm | Maximum gap mm | |||||

| d/f8 | D/H10 | L/+0.2 | Rmax | C | s* | |

| > | ≤ | |||||

| 10 | 40 | d + 10 | 16 | 0.4 | 4 | 0.25 |

| 40 | 75 | d+15 | 25 | 0.4 | 5 | 0.38 |

| 75 | 150 | d + 20 | 32 | 0.4 | 6 | 0.50 |

| 150 | 200 | d + 25 | 40 | 0.4 | 8.5 | 0.63 |

| 200 | 300 | d + 30 | 50 | 0.4 | 10 | 0.75 |

| 300 | d + 40 | 63 | 0.4 | 13 | 1.00 | |

| The extrusion gap values shown in the table above apply to temperatures below 70°C. Higher temperatures require lower extrusion gaps. | ||||||

| Operating parameters | ||||||

| Material | Temperature | Speed | Pressure | |||

| Pressure ring | Sealing ring | Support ring | Minimum °C | Maximum °C | Maximum m/s | Maximum bar (MPa) |

POM POM |

PU PU |

POM POM |

-30 | +100 | 0.5 | 500(50) |

HPU HPU |

-20 | |||||

SPU SPU |

0.7 | |||||

TPU TPU |

-40 | 0.5 | ||||

POM POM |

PU PU |

XPU XPU |

-30 | 500(50) | ||

HPU HPU |

XSPU XSPU |

-20 | ||||

SPU SPU |

0.7 | |||||

| -30 | 0.5 | |||||

PTFE g PTFE g |

NBR NBR |

PTFE g PTFE g |

250(25) | |||

FKM FKM |

-20 | +200 | ||||

EPDM EPDM |

-50 | +150 | ||||

HNBR HNBR |

-25 | |||||

| Ordering example | |

| Introduction | Rod seal TS1012-T |

| d x D x L [mm] | 100 x 120 x 23 |

| Sealing material | PU/XPU/POM |

Product classification

Label List

Previous Page

TS1315-T

Next Page

Free inquiry